Producing high quality products is our #1 priority. Investing in state-of-the art injection molding technologies, process control systems and employee training allows us to meet or exceed our

customer’s quality requirements.

All-Plastics offers documented quality at every level along with complete electronic data storage of shot-by-shot part traceability and preventative maintenance planning for our customer’s molds and for all of our support manufacturing equipment.

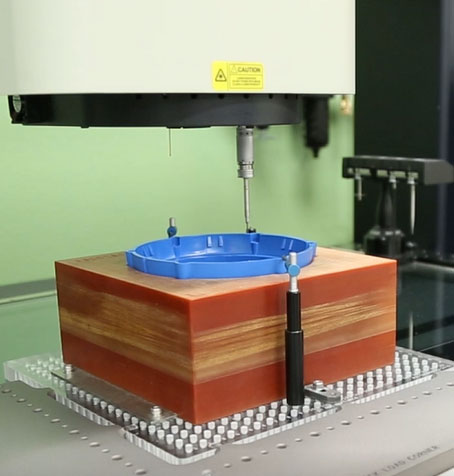

An in-house laboratory at each facility is maintained and calibrated for purposes of testing parts and/or components of parts and for the calibration and inspection, measuring and testing equipment. All tests and inspections performed are to satisfy customer’s quality testing, and regulatory expectations.

State-of-the-art equipment for accurate & consistent inspection:

-

Keyence Vision System

-

Smart Scope

Documented validation for our best in class systems and procedures we have in place:

-

ISO 13485: 2016 Certified

We offer certified clean room environments that provide contamination control and inspection.