Injection Molding in the Beauty Industry

Using injection molding in the beauty industry allows manufacturers to create products that attract customers, reduce production costs and minimize waste. In many instances, the success or failure of a product can rely on the packaging. You may have superior products, but people may fail to notice them if they’re contained in a sub-par jar, tube, pot, or bottle.

At All-Plastics, we understand the impact of packaging on sales. According to the Institut Public de Sondage d’Opinion Secteur (IPSOS), 72% of consumers in the U.S. base their purchasing decisions on the looks, appearance and design of a product’s packaging. In many instances, visual appeal can give your product an edge.

For this reason, we provide precise scientific injection molding in the beauty industry. We aim to deliver your products with aesthetic qualities that highlight your brand. In the discussion below, we’ll cover the significance and application of injection molding technology in the beauty industry. We’ll also review the benefits of injection molding products, how it impacts packaging in the beauty industry and its sustainability.

The Impact of Injection Molding

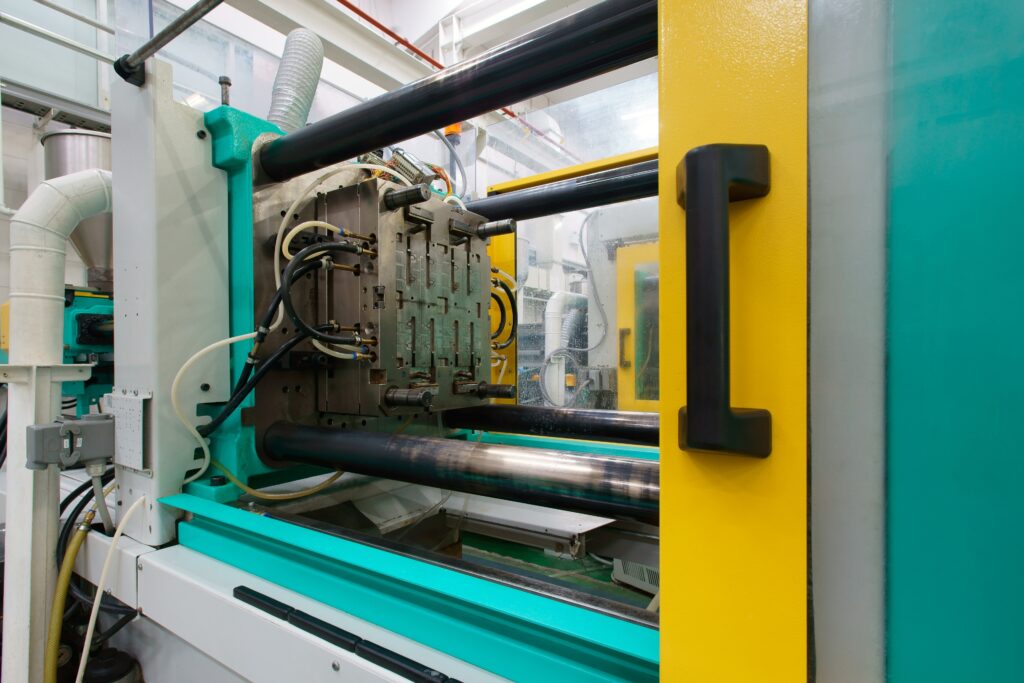

Injection molding is a process in manufacturing where plastic or other molten material is injected into a mold cavity. When the injected material solidifies and cools, it takes the desired shape according to the finished product’s design.

This process produces many products, including packaging materials, consumer goods and material parts. This highly efficient process allows manufacturers to create intricate details while maintaining aesthetics, consistency and accuracy.

The Science Behind Injection Molding Products

Injection molding is a systematic process used in packaging in the beauty industry. It follows the steps outlined below:

- The process begins with material selection, where packaging materials are selected for your product according to specific qualities such as flexibility, durability and strength.

- The mold is designed according to the type of thermoplastic that best suits your products.

- After the mold design, the material is melted and injected into the mold.

- It is then allowed to cool and solidify.

- The finished product is then ejected, and the process repeats.

Aside from the beauty industry, many sectors also benefit from this technology. Many consumer goods, medical and industrial companies rely heavily on this technology to process and package their goods.

Injection Molding in the Beauty Industry

Cosmetics packaging follows a range of containers, including rigid jars with caps, powder product containers, squeezable tubes, rigid tubes for lip glosses and similar products, pump bottles and roll-on bottles. Injection molding in the beauty industry allows manufacturers to diversify their packaging options for various product offerings. This technology also benefits their branding efforts since it can produce specific and unique designs complimenting your company’s brand voice.

Here are some of the most significant benefits of injection molding products in the beauty industry.

Precision and Consistency

Injection molding is a precise technology where accurate designs can be reproduced with great accuracy. You can include intricate designs and specific details; the final product will meet the exact specifications. This level of precision is beneficial in the beauty industry, where products are expected to be highly aesthetic and uniform.

Cost-Effectiveness

Injection molding technology uses high levels of automation, reducing the risk of human error during manufacturing. This system makes mass-producing products and containers at a lower cost possible. The final output is more durable, which can reduce the overall cost of production.

Versatility

Expect a versatile process when manufacturing containers for your beauty products. You can use this technology to create novel containers and packaging to capture the interest of potential buyers. Injection molding can utilize a variety of sizes, shapes and materials to meet customer needs.

Speed

Many companies need to mass-produce their products to match the demand from customers. In this regard, you can rely on the injection molding process to quickly produce large quantities of your product, which is ideal for meeting high demand. Since the majority of the processes are automated, using this technology allows you to create products quickly and efficiently with a very minimal margin of error.

Sustainability

Injection molding is a highly sustainable process. Many industry players take sustainability seriously, so many manufacturers use recyclable and sustainable materials. In addition, the process produces very minimal waste, and the end products can be reused repeatedly.

Multiple Options

The process of injection molding can produce resilient and aesthetically pleasing packaging options. It allows you to create a variety of designs. For instance, you can design your cosmetic products to have tabs, open/shut lids and a variety of sealing mechanisms. This allows you to create various products that can be carried anywhere, which is helpful for many consumers.

Improve Brand Awareness

The packaging components, colors, materials, prints and designs contribute to your brand voice. Injection molding technology can conform to various branding details to make your cosmetic products eye-catching and familiar to consumers.

You can also include instructions for use, pricing and other essential details in your packaging branding symbols. This effort improves brand awareness and contributes to effectively building brand loyalty.

Boost Your Branding and Packaging with All-Plastics

All-Plastics offers cutting-edge innovations in injection molding and advanced packaging. We utilize scientific injection molding technology in a zero-defect environment creating uniform products bearing your brand symbols to attract potential customers. Fill out our online contact form to request a quote or ask a question.